china ch warman slurry pump

Latest articles

What is a dredging pump?

china ch warman slurry pump...

china ch warman slurry pump 【china ch warman slurry pump】

Read MoreSlurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

china ch warman slurry pump...

china ch warman slurry pump 【china ch warman slurry pump】

Read MoreThe first major requirement for >slurry pumps is to provide adequate service life. The erosive and corrosive effects of slurries, such as the impact of high velocity flow of liquid/solid mixtures, can be really challenging. In many applications, some of the solids in the mixture are larger than the particles normally specified; therefore, the pump should be able to pass through them without causing any damage or operational problems.

china ch warman slurry pump...

china ch warman slurry pump 【china ch warman slurry pump】

Read More3. Both pumps and motors are designed separately.

china ch warman slurry pump...

china ch warman slurry pump 【china ch warman slurry pump】

Read MoreChoosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

china ch warman slurry pump...

china ch warman slurry pump 【china ch warman slurry pump】

Read MoreSlurry Pump

china ch warman slurry pump...

china ch warman slurry pump 【china ch warman slurry pump】

Read MoreDefinition of dredge and slurry pumps

china ch warman slurry pump...

china ch warman slurry pump 【china ch warman slurry pump】

Read MoreSlurry Pump

china ch warman slurry pump...

china ch warman slurry pump 【china ch warman slurry pump】

Read MoreAgain, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

china ch warman slurry pump...

china ch warman slurry pump 【china ch warman slurry pump】

Read More- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

china ch warman slurry pump...

china ch warman slurry pump 【china ch warman slurry pump】

Read More

Popular articles

- Light-duty Slurry Pump

- A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

- - Low noise level - Operating underwater results in low noise or even silent operation.

- 3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

- Make sure you follow the basic rules of pump piping.

- When flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

Latest articles

-

Choosing the right slurry pump

-

As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

-

When flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

-

Slurry Pump

-

Pump selection for FGD

-

Rubber lined pumps offer many advantages

Links

Sail making is a meticulous and skillful craft that requires precision and attention to detail. One of the most important tools in sail making is the sewing machine. A sail making sewing machine is specifically designed to handle the heavy-duty fabrics and complex stitching patterns required for creating and repairing sails.

One of the primary benefits of a domestic lockstitch sewing machine is its ability to produce high-quality seams with ease. Whether it’s garment construction or home accessories, the lockstitch provides a professional finish that can withstand wear and washing. This machine is also economical, allowing individuals to repair or create garments, resulting in significant savings compared to purchasing new items.

- Future Scalability A vision for growth can inform the decision on whether to invest in a particular machine. Choosing a machine that allows for future upgrades or adjustments can save costs in the long run.

Heavy Duty Sewing Machines: They’re faster than regular machines but not as quick as industrial ones. They can work with rigid materials but might need breaks so they don’t overheat.

The only time you REALLY need an industrial sewing machine for me would be if I wanted to sew a lot of stiff layers - those industrial machines are workhorses! Industrial heavy-duty sewing machines differ from heavy-duty home sewing machines in several ways: in speed, power, and durability, and they have specialized components designed for heavy use.

Versatility in Design

Finding the Right Machine for You

cub leather sewing machine. With its easy-to-use controls and clear instructions, you will be able to start sewing with confidence right away. Whether you are a seasoned leatherworker or just starting out, the Cub Leather Sewing Machine is perfect for crafters of all skill levels.

In addition to enhancing garment quality, incorporating an overlocker into home sewing can encourage more experimentation with different materials. Since the overlocker makes sewing with stretchy or delicate fabrics easier, enthusiasts can explore diverse projects they may have previously avoided.

The applications of the double needle sewing machine are extensive, particularly in the fashion industry. It is commonly used to sew hems, create decorative topstitching, and construct seams on garments. The parallel stitching it produces not only enhances the aesthetic appeal of clothing but also adds a layer of strength to seams, making them more resistant to wear and tear.

double machine silai machine

Conclusion

Easy to Use Heavy Duty Sewing Machine A Seamstress's Best Friend

What is a Dual Needle Sewing Machine?

When it comes to sewing, having the right equipment can make all the difference, especially if you're tackling heavy fabrics like denim, canvas, or leather. Heavy-duty sewing machines are designed to handle tough materials, providing durability and power that standard machines often lack. In this article, we will explore some of the highest-rated heavy-duty sewing machines on the market, examining their features and benefits to help you find the perfect match for your sewing projects.

The target market for a sewing machine also impacts pricing. Entry-level machines designed for beginners are affordable and user-friendly, typically aimed at hobbyists or those new to sewing. Conversely, professional-grade machines with enhanced features designed for frequent or industrial use will be much pricier. As a consumer, evaluating your skill level and sewing needs is essential—the machine suited for a casual hobbyist will be different from that required by a professional tailor or designer.

The Importance of Upholstery Stitching Machines in Modern Manufacturing

5. Walking Foot Mechanism A walking foot is a great addition for sewing leather as it helps to evenly feed the material through the machine, preventing slipping and ensuring neat seams.

heavy duty leather sewing machine for sale

The Double Needle Leather Sewing Machine An Essential Tool for Leather Crafting

3. Versatility Strong needles come in a variety of sizes and types, making them versatile enough for a range of projects. Whether you're patching up heavy work clothes, creating bags, or making upholstery, using a strong needle tailored to the task can significantly improve workflow and end results.

Final Thoughts

It is crucial to understand that there are various benefits one can get once they start using these heavy-duty sewing machines. In other words, they will offer you the comfort you need, and it will be easy to work on your project.

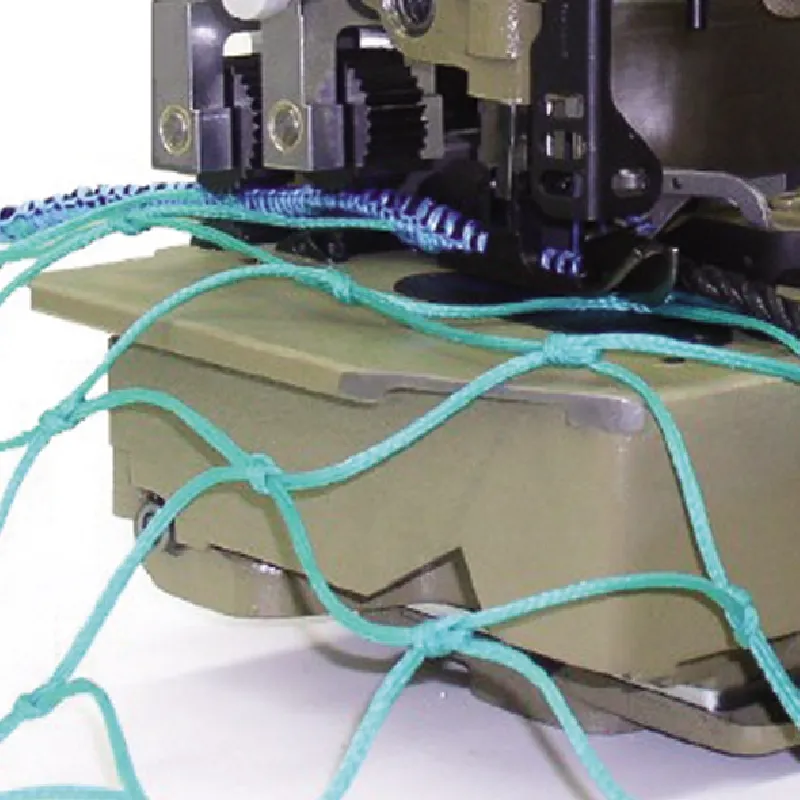

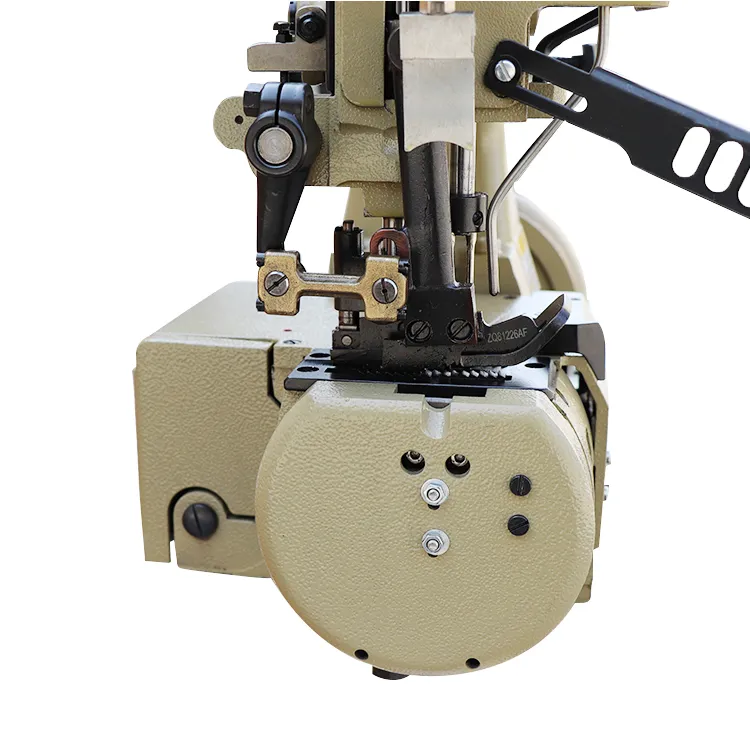

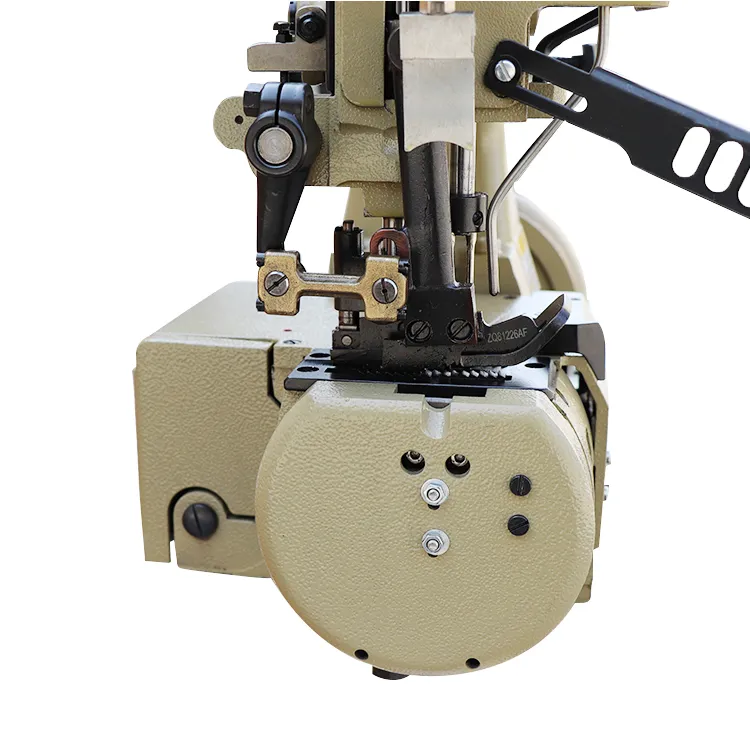

To create woven sacks, a specialized sewing machine is required. The woven sack sewing machine is a crucial piece of equipment that is used to stitch together the pieces of woven polypropylene fabric to create the final sack. These machines are designed to handle the tough and rigid material of the sacks, ensuring that the stitching is secure and durable.

One of the primary advantages of using a hand sewing machine in upholstery is versatility. Craftsmen can make adjustments to create different stitch types and lengths, allowing for a customized approach to each project. Whether it’s creating a tailored fit for a cushion or reinforcing seams for longevity, the hand sewing machine provides the flexibility needed to meet various design specifications.

In today's fast-paced world, convenience and efficiency are key factors that many consumers consider when purchasing sewing machines. Among the various innovations in the industry, self-threading sewing machines have emerged as a popular choice for both beginners and seasoned crafters alike. With the ability to simplify the threading process, these machines save time and reduce frustration, making sewing projects more enjoyable. In this article, we will explore the benefits of self-threading sewing machines and where to find them for sale.

5. Variety of Applications From garment construction to quilting and crafts, lock stitching can be used in a variety of applications, enhancing its utility in the sewing world.

Not only are these machines more affordable than brand-new models, but they are also environmentally friendly Not only are these machines more affordable than brand-new models, but they are also environmentally friendly

Not only are these machines more affordable than brand-new models, but they are also environmentally friendly Not only are these machines more affordable than brand-new models, but they are also environmentally friendly refurbished heavy duty sewing machine. By choosing a refurbished machine, you are helping to reduce waste and extend the life of a high-quality product.

refurbished heavy duty sewing machine. By choosing a refurbished machine, you are helping to reduce waste and extend the life of a high-quality product.What if you need a machine that is more industrial but you don’t have the space or the budget for a true industrial machine?

Performance and Efficiency

When you use a heavy duty industrial walking foot sewing machine- it comes with a built-in walking foot mechanism. This is very different that most walking foot attachments that only snap-on regular household sewing machines.

In addition to knitting, twin needle sewing is excellent for adding decorative elements to various fabric types. Crafters often utilize this technique to create parallel lines of straight stitches or decorative embroidery on clothing, home textiles, and accessories. Whether it’s outlining a pocket, designing a unique pattern on a garment, or adding flair to quilting projects, twin needle sewing provides versatility and creative possibilities that can significantly enhance any sewing project.

what is twin needle sewing used for

Exploring the Double Needles Chain Stitch Sewing Machine

Final Tips